| PH值 | 10 |

|---|---|

| 白度 | 93 |

| 二氧化硅含量 | 52(%) |

| 类别 | 细粉 |

| 密度 | 2.8(g/cm3)2.8-2.9(g/cm3)2.9(g/cm3) |

| 莫氏硬度 | 5.0 |

| 热膨胀系数 | 6.5*10-6 |

| 熔点 | 1540 |

| 原产地 | 江西 |

| 折光系数 | 1.616~1.631 |

| 品级 | 一级品 |

| 品牌 | 东辉 |

基本参数

基本参数 | 材料: | 硅灰石 |

|---|---|

| PH值: | 7.9-9.9 |

| 白度: | 88-93 % |

| 二氧化硅含量: | 48-52 % |

| 类别: | 针状粉 |

| 密度: | 2.7 g/cm3 |

| 莫氏硬度: | 4.5 |

| 热膨胀系数: | 6.5×10-6 |

| 熔点: | 1,544℃ ℃ |

| 原产地: | 江西 |

| 折光系数: | 1.63 |

| 品级: | 优等品 |

产品名称

塑料级硅灰石矿物纤维HJ2000-01

产品介绍

HJ2000-01是采用国家专利型粉碎设备及表面改性、超细粉碎技术对硅灰石矿进行深加工高效改性处理生产制备而成。

该产品具有高长径比纤维状特性,物化性质稳定,可与玻璃纤维或者其他填料按照一定比例组成复合填充料使用,也可以单独作为改性填充料使用。

HJ2000-01在PP、PE、PVC等通用塑料中作为填充料使用,可以在降低成本提高经济效益的同时,改善复合材料的耐热性、尺寸稳定性、表面外观、机械强度和抗划痕等性能。

另外,HJ2000-01也可用于部分工程塑料及弹性体改性中。

化学成分

偏CaSiO3为主

物化特性

表1 塑料级硅灰石矿物纤维HJ2000-01物化特性指标

| HJ2000-01 | ||

| 典型性能 | 典型值 | 备注 |

| 白度 | 90±2 | DN-B数显白度仪 |

| 吸油值(g/100g) | 35/45/45 | ASTM D281 |

| 折射率 | 1.63 |

|

| pH值(10%悬浮液) | 9.9 |

|

| 莫氏硬度 | 4.5 |

|

| 膨胀系数(mm/mm/℃) | 6.5×10-6 | ASTM 696 |

| 平均粒径D50(μm) | 7.5 |

|

| 平均长径比 | 5:1-10:1 | 显微镜法 |

| 疏松密度(g/ml) | 0.8/0.6/0.6 | ASTM C87 |

| 熔点(℃) | 1410 | ASTM D 1875 |

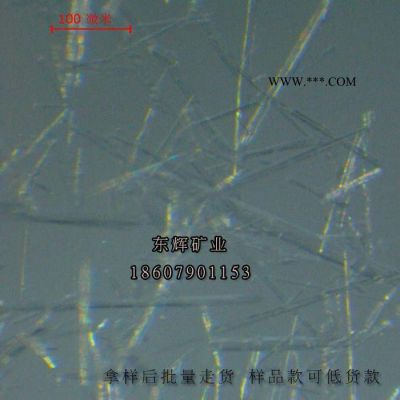

纤维形态及粒径分布曲线

图1 纤维形态图 图2 粒径分布图曲线图

产品主要特点

-改善拉伸强度、弯曲强度等机械性能;

-提高模量

-提高硬度及刚性

-提高耐热性能及热变形温度

-提高抗划痕性能

-改善表观性能

-部分替代短玻纤维,降低成本

应用领域

HJ2000-01主要用于聚乙烯(PE)、聚丙烯(PP)、聚氯乙烯(PVC)、聚苯乙烯(PS)及ABS等通用塑料中,也可用于部分工程塑料及弹性体改性中。

使用方法

与玻璃纤维或者其他填料按照一定比例组成复合填充料使用,添加位置与玻璃纤维或者其他填料一致。

单独作为填充料使用,添加位置为侧喂料口。

运输包装与储存方式

25Kg/袋或吨袋包装,本品不属易燃易爆物,无毒无害,可按一般矿物产品运输。

适合在干燥通风处储存,避免雨淋或水湿。

保质期

半年